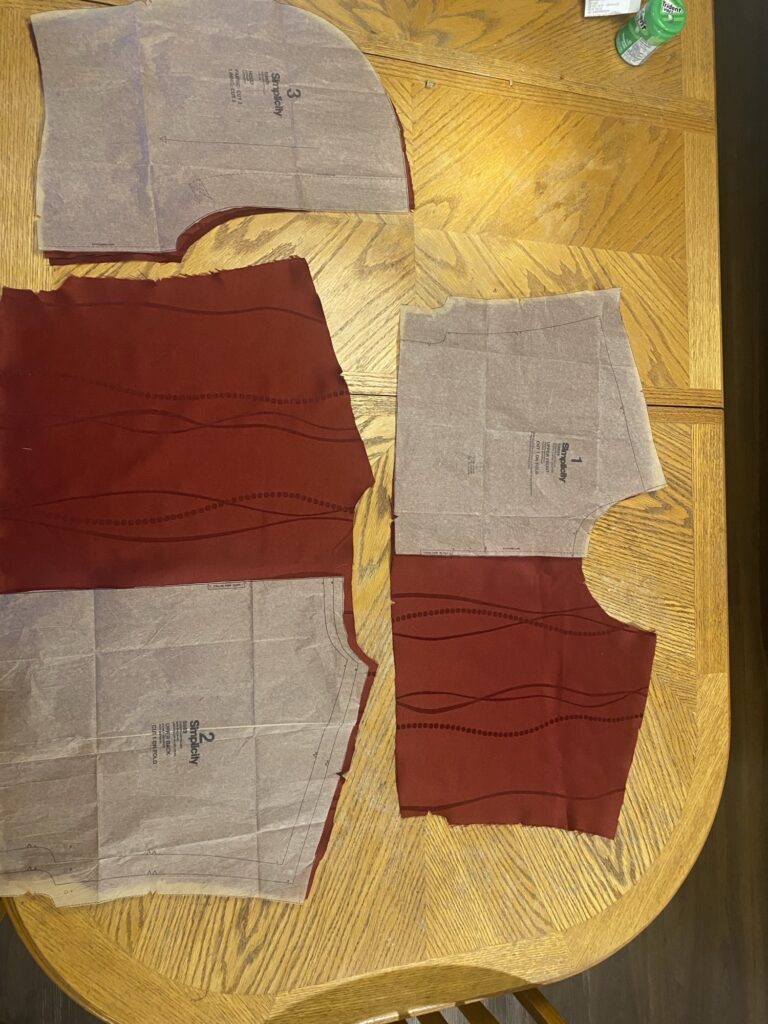

Last week, after learning all about the intricacies of patterns, I started my project. First, I carefully cut out the pattern for the hoodie I wanted to design. For the Fabric, I have chosen several different tablecloths that I found secondhand because I thought this material would be easy to work with (because it’s thin) and affordable (around 4 dollars). After I had the pattern outline on paper, I spread out my fabric and placed and pinned the paper pattern on top. As I started cutting the pattern out, I noticed that the edges unraveled as the fabric was cut. However, I pressed on. Most of the outside edges would be covered anyway by either folding them and creating a seam or by making sure the attachment point was on the inside of the garment. The next step was to clean and oil the machine as my sewing partner Anne had taught me. I carefully cleaned it and set all the dials for the fabric. Straight seam, low needle pressure, and short stitches due to the delicacy of the material.

The Problem

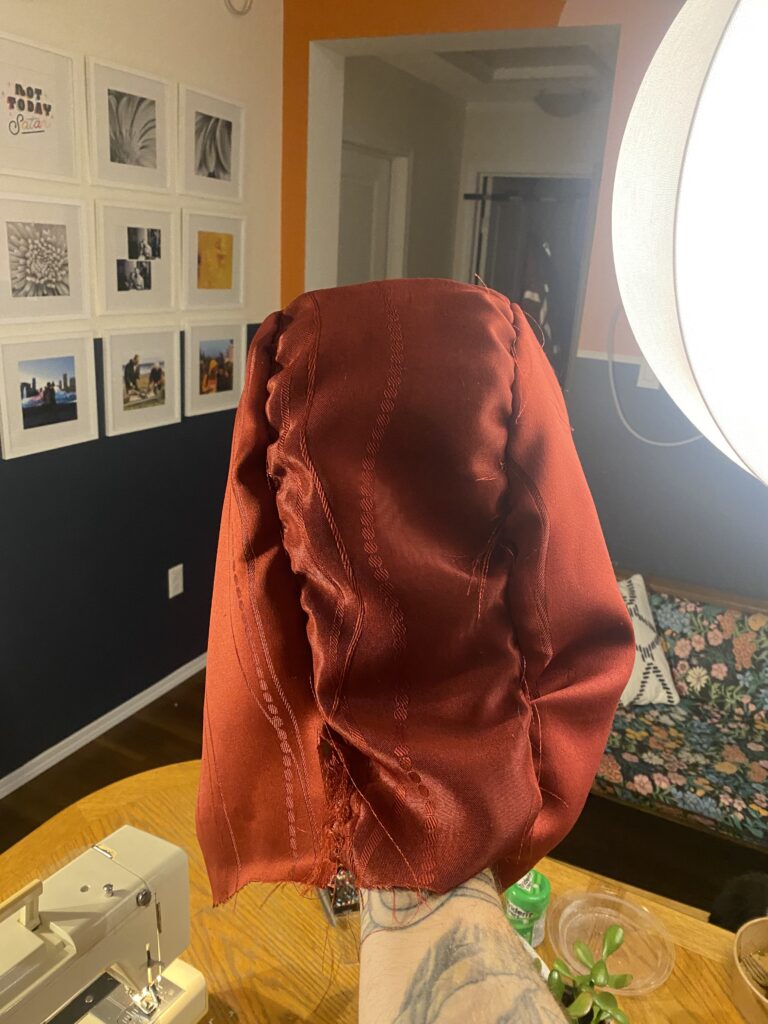

It was after all my prep that the problems began. The fabric I had chosen needed to be thicker. As the needle worked, it was punching holes that were too big. Because the frayed edges I mentioned earlier were coming apart, the fabric began to disintegrate as it worked through the machine. The thread I was sewing with was steadily bunching as it pulled the garment together in weird places. “I will fix this later,” I thought, wanting to get an outline and more experience with the machine. Moving forward, I began to construct the hood of the garment. This presented its challenges as I had to sew the hood using some curved lines to give the hood shape. I continued to work with the material. But after a few more seams, I heard Anne’s words of wisdom: “If you don’t start properly, it’s not worth starting.” It was back to the drawing board.

Below is the top section of the hoodie with the edges damaged, as well as the beginning of the hood.

Conclusion.

I have learned that choosing the correct material is an essential part of the process. Although my main focus was being able to upcycle materials, I will need to learn what materials can be made into what garments. Another epiphany I had was that pinning the paper on the fabric and cutting out the shapes that need to be sewn takes a long time (almost 2.5 hours). In my future projects, I will combat this by finding patterns I like and tracing them out on thin rubber. This way, the patterns will be easier to store and much more robust. I will also be buying an automated power cutter. The cutter will speed up the process and allow for smoother cuts than shears (I love an excuse to buy power tools). Beyond these few hang ups getting started on the project was a success. This endeavor undoubtedly challenges me to use a growth mindset and keep failing forward.

Photo Credit for Featured image from Unsplash

Photo by frank mckenna on Unsplash