I browsed the racks at our local Winner’s department store this summer. There were hundreds of shirts from brands like Calvin Klein, H&M, Nike, and more. When a simple hoodie with an exciting design caught my eye, I took my hand and felt the fabric; it was a good weight. It felt expensive; the seams were double stitched, and the garment was even in my size. With trepidation, I looked for the tag. I was astonished to find this hoodie was marked down to $19.99. The tag also read “Made in China”. Immediately, I snatched the Hoodie, took it into my arms, and walked to the register to buy it. However, on the drive home, something didn’t sit right. How could this hoodie be so cheap? And how did it find its way into my arms from a factory in China for less than the cost of lunch? To zoom in for a moment, let’s think of the supply chain events that would need to happen for me to own this immaculate piece of clothing.

First, somewhere in the world, someone created the raw materials to make this hoodie. Thread, cotton, and polyester. It is already a Herculean feat to process all that material, pack it, make fabric, and then ship it to a factory in China. Second, a research and development team in the Chinese factory designed, marketed and created an assembly line to make this specific piece of clothing. All those people were paid wages and likely paid taxes. Third, the company packed and shipped this hoodie to somewhere in North America, where it was unloaded in a harbor, put on a truck, and sent to a department store. The hoodie was then unpacked again and put on the shelf. After weeks of not being sold (no accounting for people’s taste), the hoodie was repacked and likely bundled with several other products to be sent to a discount brand like Winners in my town. Once the hoodie arrived, it was itemized, given a tag, and put on another shelf to be sold at a discount to a fortunate buyer, “Me” in a small town in Canada, and all for the low, low price of $19.99. This example is only the tip of the iceberg. There are dozens more steps in that process, and they all cost money. You might now ask yourself as I did, “How is this possible?” The short answer is worker exploitation and the destruction of the environment. An article on davidsuzuki.org provides commentary on this issue: “A survey conducted in a textile mill in India found that 60 percent of employees were under the age of 18 when they began working” (Suzuki). The article then makes claims about the environment, stating, “35% of primary microplastics in the ocean are from washing synthetic textiles. These release 0.5 billion kilograms of microplastic fibers into the sea yearly (Suzuki).

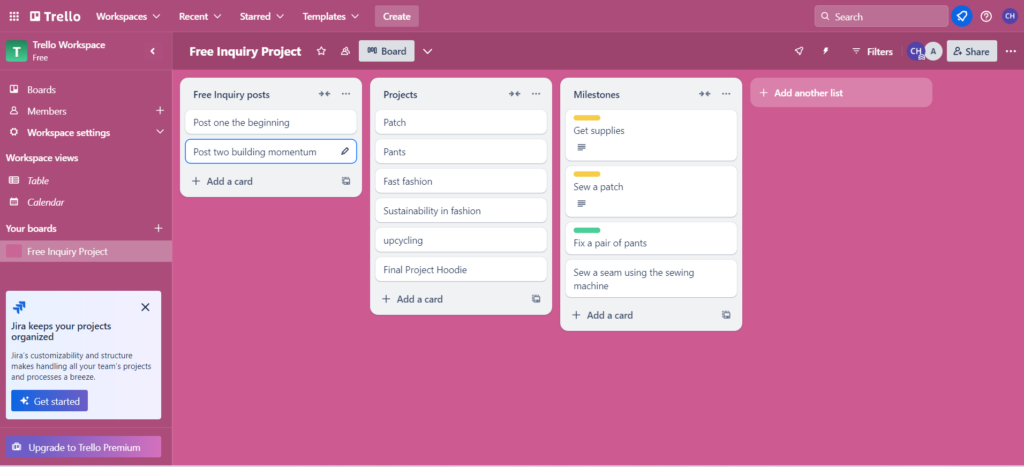

Reflecting on this process has led me to my free inquiry project. I want to learn to sew, create, and design my clothing from thrift items. In the long term, I hope to extend the project to make sewing and garment design more accessible to those around me so that they can create clothing that looks and feels good by upcycling materials that would otherwise be discarded in a landfill. When I have brought up sewing to my peers, the most common response I get about it is, “Oh, my grandma likes to do that in her spare time.” The rise of fast fashion and cheap garments has allowed society to move to a place where it’s more affordable to buy a new hoodie for $19.99 than fix, maintain, or create one from repurposed materials. The first step in my project is to build a Trello board to track objectives during my sewing journey. With a plan in place and some milestones set, I will begin my journey to more ethically sourced and curated clothing, saving the environment and hopefully tuning out a look or two! So join me in my journey, my savvy seamsters, as we take on the fashion industry and build the skills to create a dazzling wardrobe.

Citations

(n.d.). The Environmental Cost of Fast Fashion. David Suzuki Foundation One Nature. Retrieved September 23, 2024, from https://davidsuzuki.org/living-green/the-environmental-cost-of-fast-fashion/